Explain the twin tub process with a neat diagram.

March 05, 2024

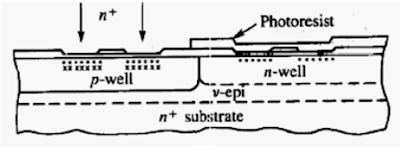

Twin-tub process:

Step 1:

n- Substrate is taken initially, which is shown in figure.

Step 2:

Next step is epitaxial layer deposition. Lightly doped epitaxial layer is deposited above nsubstrate.

Step 3:

The next step is tub formation. Two wells are formed namely n-well and p-well.

Polysilicon layer is formed above overall substrate.

Step 4:

Polysilicon gates are formed for n-well and p-well by using photo-etching process.

Step 5:

n+ diffusion is formed in n-well, P+ diffusion is formed in p-well. These are used for VDD contact and VSS contact. These are known as substrate formation.

Step 6:

Then, contact cuts are defined as in n-well process. Then metallization is processed.

|

| Twin-tub process |