CMOS DEVICES & TECHNOLOGIES

The four main CMOS technologies are

n-Well process

p-Well process

Twin-tub Process

Silicon on Insulator

Explain the different steps involved in CMOS fabrication / manufacturing process with neat diagrams. (Nov 2007, Nov 2009, Nov 2016, NOV 2018)

Describe with neat diagram the n-well and channel formation in CMOS process. (Nov/Dec 2014)(Nov/Dec 2011) (April/May 2011) (Nov/Dec 2012)

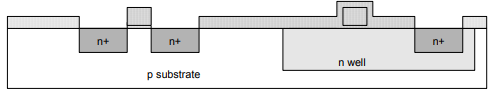

n-WELL PROCESS:

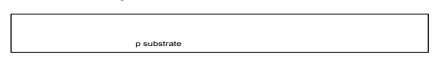

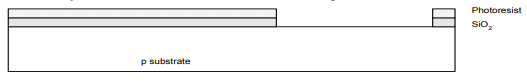

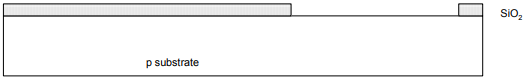

Step 1: Start with blank wafer

First step will be to form the n-well

– Cover wafer with protective layer of SiO2 (oxide)

– Remove layer where n-well should be built.

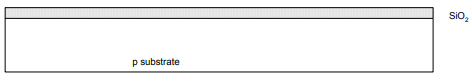

Step 2: Oxidation

Grow SiO2 on top of Si wafer, at 900 – 12000 C with H2O or O2 in oxidation furnace.

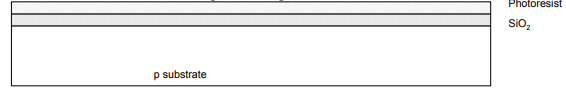

Step 3: Photoresist

• Spin on photoresist

– Photoresist is a light-sensitive organic polymer.

– Softens, where exposed to light.

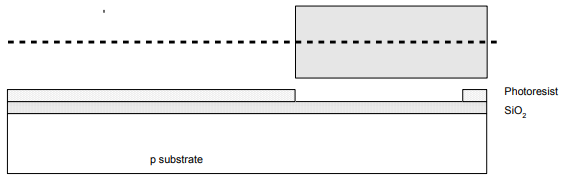

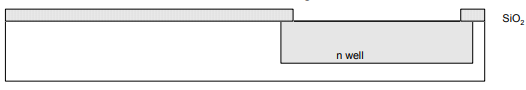

Step 4: Lithography

• Expose photoresist through n-well mask.

• Strip off exposed photoresist.

Step 5: Etch

• Etch oxide with hydrofluoric acid (HF).

• Only attracts oxide, where resist has been exposed.

Step 6: Strip Photoresist

• Etch the remaining photoresist using a mixture of acids.

Step 7: n-well

n-well is formed with diffusion or ion implantation.

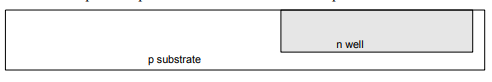

Step 8: Strip Oxide

• Strip off the remaining oxide using HF.

• Back to bare wafer with n-well.

• Subsequent steps involve similar series of steps.

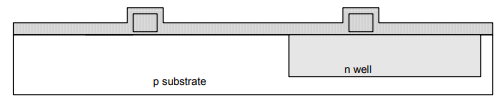

Step 9: Polysilicon

• Deposit thin layer of oxide. Use CVD to form poly and dope heavily to increase conductivity.

Step 10: Polysilicon Patterning

• Use same lithography process to pattern polysilicon.

Step 11: Self-Aligned Process

Cover with oxide to define n diffusion regions.

Step 12: N-diffusion

• Pattern oxide, using n+ active mask to define n diffusion regions.

• Diffusion or ion implantation is used to create n diffusion regions.

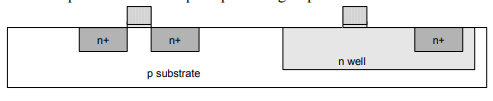

Step 13:

• Strip off oxide to complete patterning step.

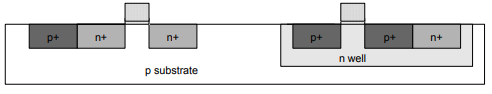

Step 14: P-Diffusion

• Similar set of steps are followed to form p+ diffusion regions for pMOS source and drain and substrate contact.

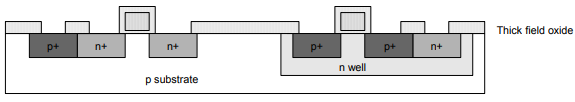

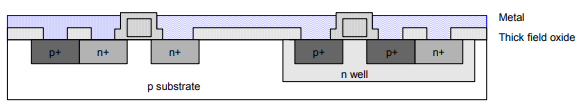

Step 15: Contacts

• Now, we need to wire together the devices.

• Cover chip with thick field oxide.

• Etch oxide, where contact cuts are needed.

Step 16: Metallization

• Sputter on aluminum over whole wafer.

• Pattern to remove excess metal, leaving wires.

P-WELL PROCESS:

A common approach to p-well CMOS fabrication is to start with moderately doped n-type substrate (wafer), create the p-type well for the n-channel devices and build the p-channel transistor in the native n-substrate.

Explain the twin tub process with a neat diagram. (Nov 2007, April 2008)

Twin-tub process:

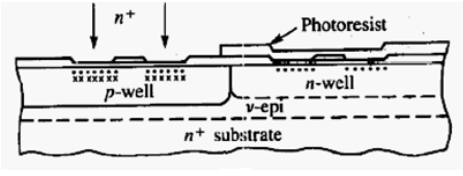

Step 1:

n- Substrate is taken initially, which is shown in figure.

Step 2:

Next step is epitaxial layer deposition. Lightly doped epitaxial layer is deposited above nsubstrate.

Step 3:

The next step is tub formation. Two wells are formed namely n-well and p-well.

Polysilicon layer is formed above overall substrate.

Step 4:

Polysilicon gates are formed for n-well and p-well by using photo-etching process.

Step 5:

n+ diffusion is formed in n-well, P+ diffusion is formed in p-well. These are used for VDD contact and VSS contact. These are known as substrate formation.

Step 6:

Then, contact cuts are defined as in n-well process. Then metallization is processed.

|

| Twin-tub process |